Trolleys

About

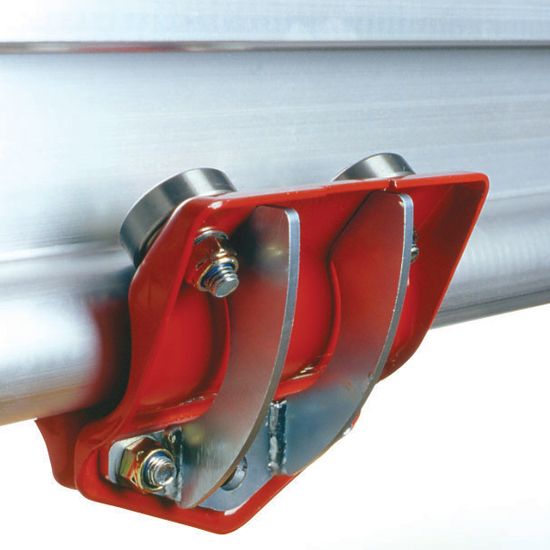

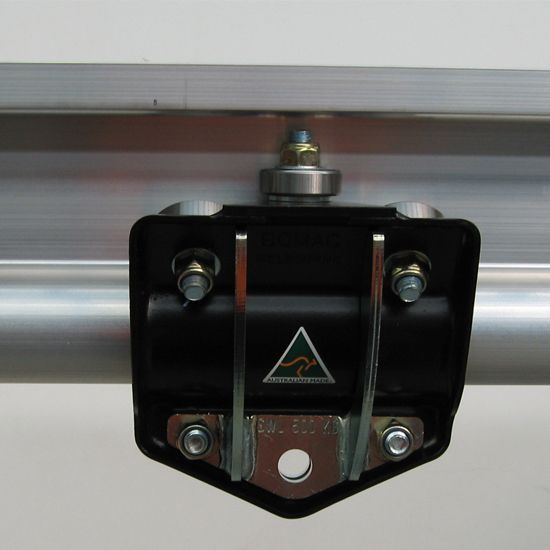

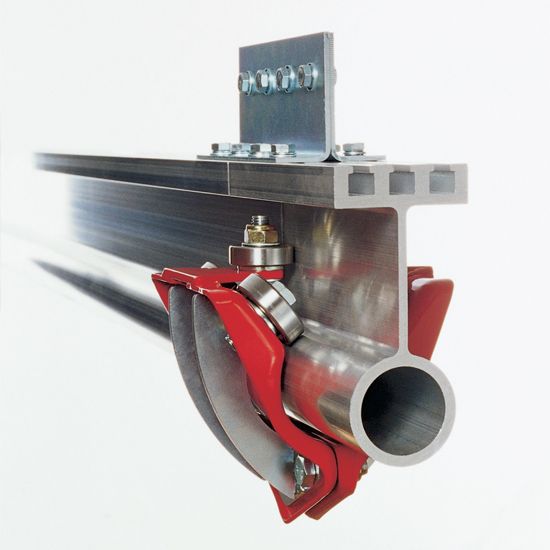

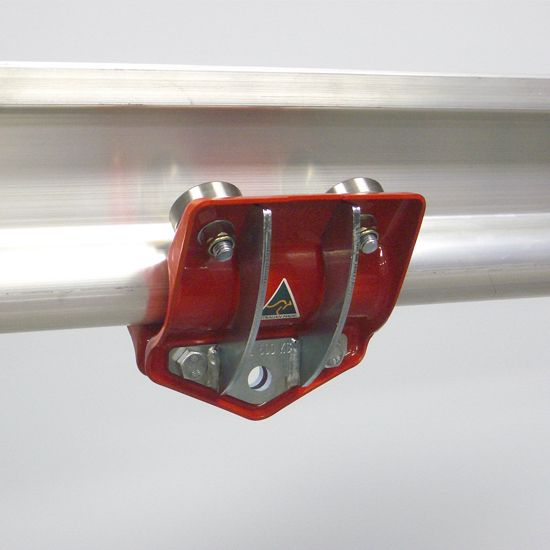

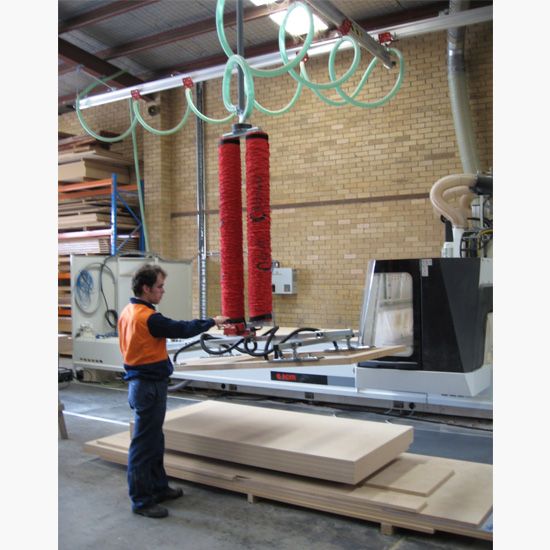

Altrac trolleys have been designed with four load wheels for even weight distribution and low rolling resistance to provide easy movement, so it does the work and not the operator.

Various wheel configurations allow for accidental side and uplift loads that may occur in some operations. While a variety of wheel options can cater for various applications such as industrial, marine and dusty environments.

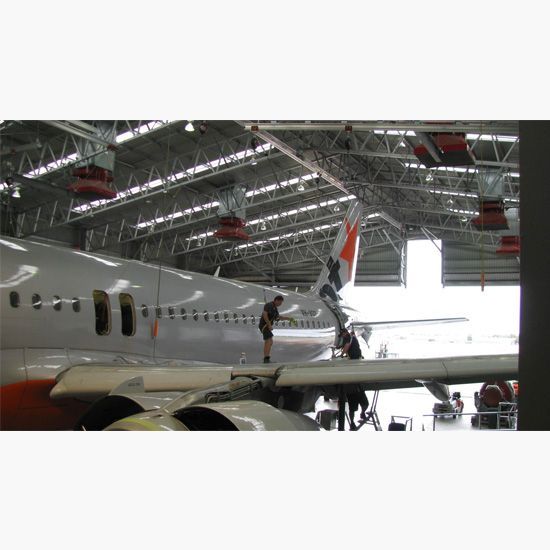

The trolleys can also be tailored to meet the requirements of different industries such as theatre, food production or clean room facilities. This means you can optimise the unit for your objective.

For applications where manual movement of the trolley may not be possible such as non-trafficable areas due to various hazards Bomac can offer a motorised carriage for the trolley.

The various options are outlined under the technical specifications tab.

Benefits

- MAINTENANCE

Any maintenance is easily identifiable as Trac trolleys run externally on Altrac - not hidden and held captive by enclosed track thus requiring removal for inspection.

- FREE RUNNING

Less than 0.5% rolling resistance enables you to move the load without strain. Less effort required than beam/enclosed track systems.

- ADD/REMOVE TROLLEYS

Trac trolleys may be added or removed anywhere along the line of an Altrac system and this can be achieved without removing the existing Trac trolleys. Enclosed track systems do not have this flexibility.

- NON-JAMMING

The design of the trolleys means they will not twist or slew to cause jamming.

- TESTED

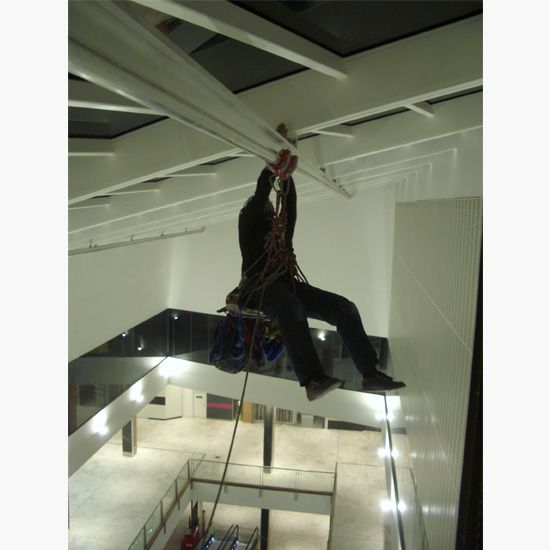

All rated trolleys comply to Australian Crane Code Standards available in a range of configurations in accordance with AS1418 and AS1891.2 - Fall Arrest Systems.

Unrated trolleys are available for non-hoisting applications and can support up to 150kg as a static load.

Technical Specification

TROLLEY OPTIONS:

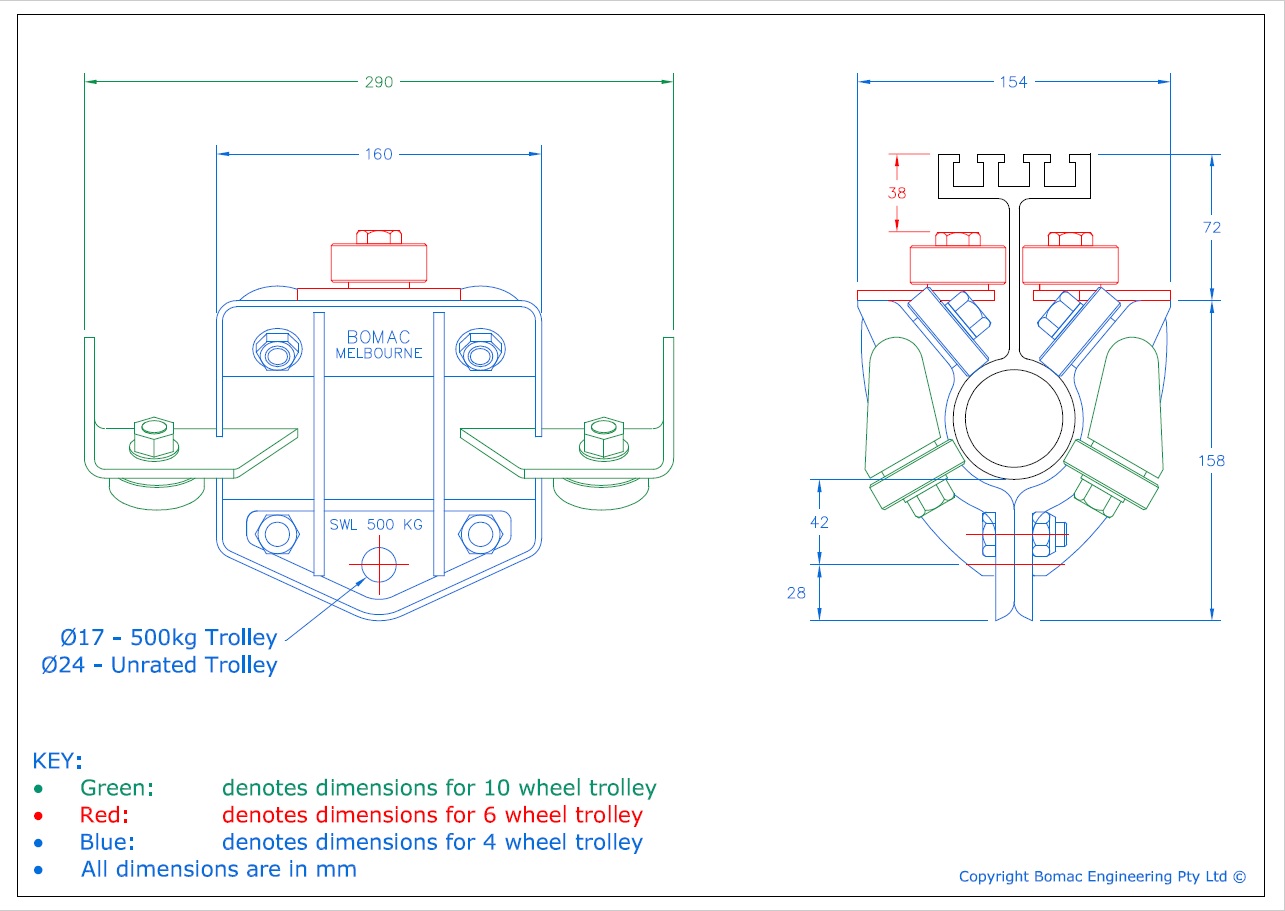

- WHEEL CONFIGURATION

4 Wheel – Basic model for simple load suspension

6 Wheel – Fitted with 4 load and 2 side guide wheels to accommodate incidental side loading that may occur when negotiating bends or off centre loads

10 Wheel - 10 bearing wheels provide guidance in all directions. Suitable for end carriages on gantry cranes and incidental uplift applications

- RATINGS

Unrated - Unrated trolleys have a maximum capacity 150kg (not to be used for hoisting applications)

500kg - Rated for 500kg load in accordance with AS1418. 1000kg capacity available using 2 trolleys and load bar.

Fall arrest/Rope access applications - In accordance with AS1891 and AS 4488 our 500kg rated trolleys can be used for fall arrest and rope access applications. Please note for rope access usage two trolleys are required per user

- FOOD GRADE/CORROSION RESISTANT GRADE OPTIONS

For applications within hygienic standards or highly corrosive environments we offer trolleys that are zinc plated and E-coated for greater corrosion resistance with stainless steel components. For non-food applications the trolley may be powder coated for additional protection

- POWERED CARRIAGE OPTION

Proportionate tractive effort.

Patented friction drive

Various single speed options 1-15 metres per minute.

3Ph 415V motor (standard)

Electrical supply via collector rail or flat cable catenary.

- TROLLEY FINISH OPTIONS:

SIDEPLATE:

Powder Coat - Standard 'Signal Red'

E-Coat Black

Galvanised

BEARING:

Shielded

Sealed

Open

WHEEL:

Steel

Nylon Tyre

Stainless Steel